Gas Pressure Reducing Valve

Factory direct price, MOQ starting from 1 piece, free sample available.

One-stop valve service provider.

Over 20 years of experience.

Product Categories

Send Your Inquiry Today

Gas Pressure Reducing Valve

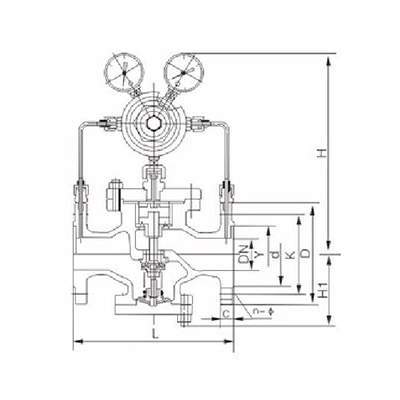

Structural features and uses

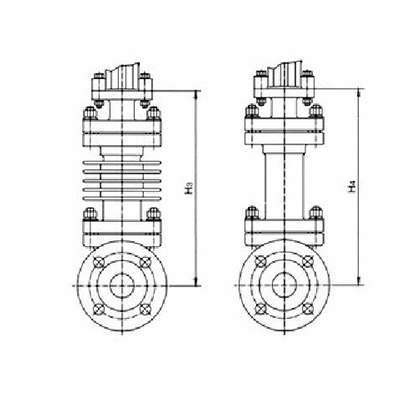

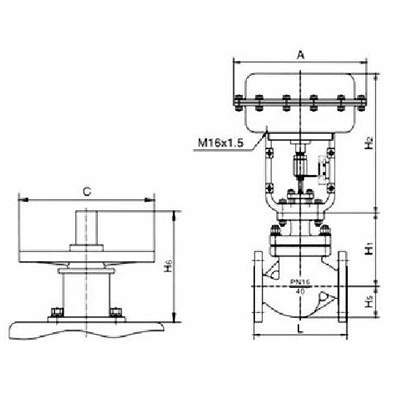

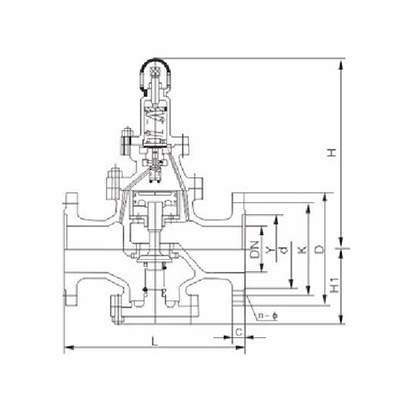

This series of pressure reducing valves are pilot piston type pressure reducing valves. They consist of two parts: the main valve and the pilot valve. The main valve is mainly composed of valve seat, main valve disc, piston, cylinder sleeve, spring and other parts.

The pilot valve is mainly composed of valve seat, valve disc, diaphragm, spring, regulating spring and other parts. The outlet pressure is set by adjusting the pressure of the regulating spring, the outlet pressure is sensed by the diaphragm, and the size of the flow area of the main valve throttling part is adjusted by the pilot valve opening and closing to drive the piston to achieve the pressure reduction and stabilization function.

This product is mainly used for gas pipelines, such as air, nitrogen, oxygen, hydrogen, liquefied gas, natural gas and other gases.

In stock

Main technical parameters and performance indicators

| Nominal pressure(MPa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16 |

| Shell test pressurea(MPa)* | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24 |

| Sealing test pressure(MPa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16 |

| Maximum import pressure(MPa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

| Export pressure range(MPa) | 0.1-1.0 | 0.1-1.6 | 0.1-2.5 | 0.5-3.5 | 0.5-3.5 | 0.5-4.5 |

| Pressure characteristic deviation(MPa)△P2F | GB12246—1988 | |||||

| Flow characteristic deviation(MPa)△P2G | GB12246—1989 | |||||

| Minimum pressure difference(MPa) | 0.15 | 0.15 | 0.2 | 0.4 | 0.8 | 1 |

| Leakage rate | X/F(PTFE/Rubber):O Y(Hard seal):GB12245—1989 | |||||

Main Parts Materials

| Part name | Part material |

| Valve body, valve cover, bottom cover | WCB/FCB* |

| Valve seat disc | 2Cr13/304* |

| Cylinder liner | 25(Hard chrome plating)/304* |

| piston | 2Cr13/copper alloy* |

| Piston ring | Alloy cast iron/Para polystyrene* |

| Guide valve seat and guide valve stem | 2Cr13/304* |

| diaphragm | 1Cr18Ni9Ti |

| Main valve guide valve spring | 50CrVA |

| Adjust the spring | 60Si2Mn |

| a seal(X/F model) | Rubber/PTFE |

| Valve body and valve cover | 25/304 |

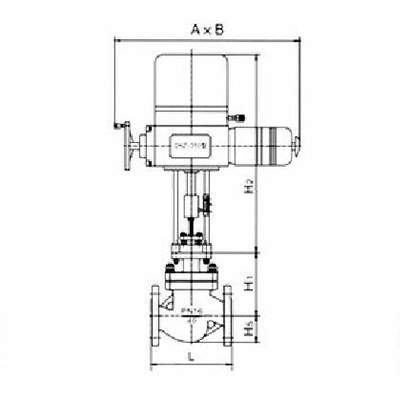

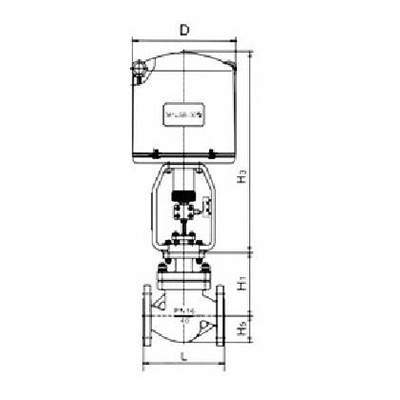

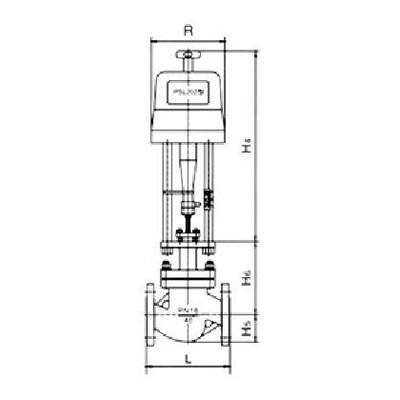

Related Products

Customize Your Valve!

Tell Us Your Requirements

Provide valve details such as size, pressure, material, etc.

You can also upload datasheets or drawings directly.

You can also upload datasheets or drawings directly.

Receive a Quote and Solution ≤ 2 Hours

Fill out this form to get a quote and solution in less than 2 hours, making your projects easier to manage and purchases smoother.

Get Drawings and Datasheets ≤ 6 Hours

For standard valves, we deliver drawings or datasheets within 6 hours. For custom valves or large projects, we can provide them within 24 hours.

Get a quote