Butterfly Valve

Factory direct price, MOQ starting from 1 piece, free sample available.

One-stop valve service provider.

Over 20 years of experience.

Product Categories

Send Your Inquiry Today

Butterfly Valve

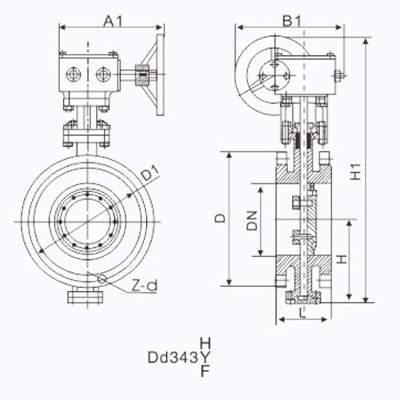

Product structure

The multi-layer hard seal butterfly valve series products are newly developed by our company with long life and energy saving. Its structure adopts the three-dimensional eccentric principle design, and the valve seat adopts a hard seal compatible multi-layer structure, with exquisite processing and advanced technology. This product consists of valve body, butterfly plate, multi-layer valve seat, valve stem, transmission mechanism and other main components.

Features

Because the butterfly valve of this product adopts the three-dimensional eccentric principle design, the spatial motion trajectory of the sealing surface is idealized, and there is no friction and interference between the sealing pairs. In addition, the sealing material is properly selected, so that the sealing, corrosion resistance, high temperature resistance and wear resistance of the butterfly valve are reliably guaranteed. Its main features are as follows:

- Small opening torque, flexible and convenient, labor-saving and energy-saving;

- The three-dimensional eccentric structure makes the butterfly valve plate tighter and tighter, and its sealing performance is reliable, achieving no leakage;

- High pressure resistance, corrosion resistance, wear resistance, long service life, etc. "

In stock

Main technical parameters

| Nominal diameter | DN(mm) | 50~4000 | 50~2600 | ||||

| Nominal pressure | PN(mm) | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | |

| Test pressure PS(MPa) |

strength test | 0.9 | 1.5 | 2.4 | 3.75 | 6.0 | |

| Sealing test | 0.66 | 1.1 | 1.76 | 2.75 | 4.4 | ||

| Airtight seal test | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | ||

| Test standards | GB/T13927-91 standard | ||||||

| Applicable temperature | carbon steel:-29℃~425℃ stainless steel:-40℃~600℃ | ||||||

| Applicable media | Air, water, steam, coal gas, oil products, as well as weak corrosive media such as acids, alkalis, and salts | ||||||

| Drive form | Worm gear transmission, pneumatic transmission, electric transmission | ||||||

Main component materials

| Parts Name | Material | ||||||

| valve body | Cast steel, ductile iron, carbon steel, stainless steel, chromium molybdenum steel, alloy steel | ||||||

| Disc | Cast steel, ductile iron, alloy steel, stainless steel, chromium molybdenum steel | ||||||

| seal ring | Stainless steel and high-temperature resistant stone slabs are combined into multiple layers | ||||||

| Valve stem | 2Cr13、1Cr13 Stainless steel, chromium molybdenum steel, duplex steel | ||||||

| Bearing | Austenitic stainless steel, 304 nitriding | ||||||

| filler | Flexible graphite | ||||||

Related Products

Customize Your Valve!

Tell Us Your Requirements

Provide valve details such as size, pressure, material, etc.

You can also upload datasheets or drawings directly.

You can also upload datasheets or drawings directly.

Receive a Quote and Solution ≤ 2 Hours

Fill out this form to get a quote and solution in less than 2 hours, making your projects easier to manage and purchases smoother.

Get Drawings and Datasheets ≤ 6 Hours

For standard valves, we deliver drawings or datasheets within 6 hours. For custom valves or large projects, we can provide them within 24 hours.

Get a quote