Fluorine Lined Gate Valve

Factory direct price, MOQ starting from 1 piece, free sample available.

One-stop valve service provider.

Over 20 years of experience.

Product Categories

Send Your Inquiry Today

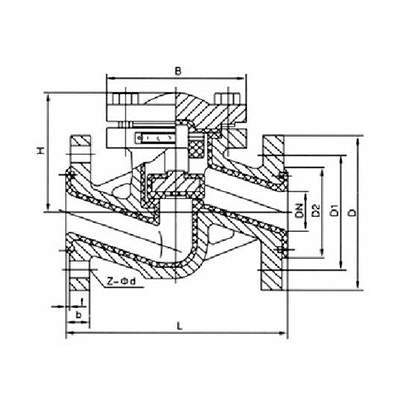

Fluorine Lined Gate Valve

FEP (F46) and PCTFE (F3) fluorine-lined gate valves are suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids, and strong oxidants at -50℃~150℃. FEP is also suitable for use in pipelines with various concentrations of strong alkali organic solvents and other corrosive gases and liquid media.

Z41F46 、F3-10、10C、10P Z41F46、F3-16、16C、16P、Z41F46 、F3-25 、25C 、25P、ANSI、150Lb、300Lb

Fluorine lined butterfly valve standard

| Technical specification | |

| Design standard | GB12238 |

| Structural length | GB12221 |

| Flange standard | HG20592 |

| Inspection test | GB/T9119-2010 |

| Drive mode | GB/T13927 |

In stock

Main parts materials

| Number | Parts Name | Ductile iron | Cast steel | Stainless steel | Ultra-low carbon stainless steel | ||

| Q | C | P | R | PL | RL | ||

| 1 | Valve body, bonnet, gate | QT450-10 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Lining layer/valve seat | PCTFE(F3)PVDF(F2)FEP(F46)PFA(Soluble polytetrafluoroethylene)Po | |||||

| 3 | Valve stem | 1Cr13 | 2Cr13 | Cr18Ni9 | Cr18Ni12Mo2T | 00Cr18Ni10 | 00Cr17Ni14Mo2 |

| 4 | Packing, gasket | Flexible Graphite P T F E ( F 4 ) | |||||

| 5 | Middle flange screw | 35 | 35 | 1Cr17Ni2 | Cr17Ni2 | 1Cr18Ni9 | 1Cr18Ni9 |

| 6 | Middle flange screw | 45 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

| 7 | Bracket | HT250WCB CF8 | |||||

| 8 | Valve stem nut | ZCuAi10Fe3 A439 D2 | |||||

| 9 | Handwheel | KT330-08WCC | |||||

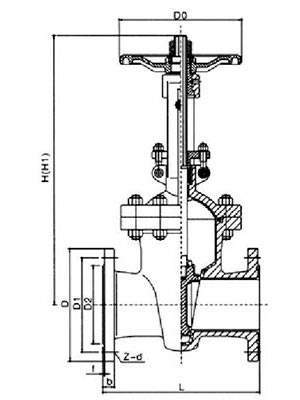

Main shape and connection dimension

| Nominal diameter | Standard value | Reference value | ||||||||||

| DN(mm) | NPS(in) | L | D | D1 | D2 | z-φd | Do | H | H1 | W(kg) | ||

| PN (MPa) | ||||||||||||

| 15 | 1/2 | 130 | 95 | 65 | 45 | 2 | 14 | 4-14 | 120 | 110 | 25 | 6 |

| 20 | 3/4 | 150 | 05 | 75 | 55 | 16 | 4- 14 | 40 | 40 | |||

| 25 | 1 | 160 | 15 | 85 | 65 | 16 | 4-14 | 140 | 132 | 55 | 8 | |

| 32 | 11/4 | 180 | 35 | 100 | 78 | 18 | 4-18 | 160 | 156 | 85 | 11 | |

| 40 | 11/2 | 240 | 45 | 110 | 85 | 18 | 4-18 | 200 | 167 | 210 | 20 | |

| 50 | 250 | 60 | 125 | 100 | 20 | 4-18 | 200 | 358 | 410 | 28 | ||

| 65 | 21/2 | 270 | 80 | 145 | 20 | 20 | 4-18 | 250 | 375 | 440 | 32 | |

| 80 | 3 | 280 | 195 | 160 | 135 | 22 | 4-18 | 250 | 435 | 515 | 45 | |

| 100 | 4 | 300 | 215 | 180 | 155 | 22 | 3-18 | 280 | 500 | 600 | 60 | |

| 125 | 5 | 325 | 245 | 210 | 85 | 24 | 8-18 | 280 | 615 | 740 | 10 | |

| 150 | 9 | 350 | 280 | 240 | 210 | 24 | 23 | 400 | 675 | 325 | 20 | |

| 200 | 8 | 400 | 335 | 295 | 265 | 26 | 8- 23 | 400 | 820 | 1020 | 50 | |

| 250 | 10 | 450 | 390 | 350 | 320 | 28 | 12–23 | 450 | 970 | 1220 | 240 | |

| 300 | 12 | 500 | 440 | 400 | 368 | 28 | 12- 23 | 500 | 1145 | 1445 | 340 | |

| 350 | 14 | 550 | 500 | 460 | 428 | 30 | 16–23 | 600 | 1280 | 1630 | 550 | |

| 400 | 16 | 600 | 565 | 515 | 482 | 32 | 16–25 | 600 | 1450 | 1850 | 680 | |

| 450 | 18 | 650 | 615 | 565 | 532 | 32 | 20-25 | 650 | 1538 | 1988 | 795 | |

| 500 | 20 | 700 | 670 | 620 | 585 | 4 | 34 | 20–25 | 650 | 1730 | 2230 | 880 |

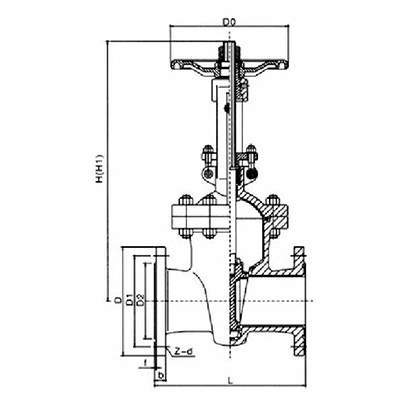

Main shape and connection dimensions

| Nominal diameter | Standard value | Reference value | ||||||||||

| DN(mm) | NPS(in) | L | D | D1 | D2 | z-φd | Do | H | H1 | W(kg) | ||

| Pa) | ||||||||||||

| 15 | 1/2 | 30 | 95 | 65 | 45 | 4-14 | 120 | 110 | 125 | 7 | ||

| 20 | 3/4 | 105 | 75 | 55 | 16 | 14 | 20 | 140 | 8 | |||

| 25 | 1 | 60 | 115 | 85 | 65 | 2 | 16 | 4-14 | 140 | 132 | 155 | 9 |

| 32 | 11/4 | 80 | 135 | 00 | 78 | 18 | 4-18 | 160 | 156 | 185 | 13 | |

| 40 | 1/2 | 240 | 145 | 10 | 85 | 18 | 4-18 | 200 | 167 | 210 | 25 | |

| 50 | 2 | 250 | 160 | 25 | 00 | 3 | 20 | 4-18 | 200 | 358 | 410 | 32 |

| 65 | 21/2 | 270 | 180 | 45 | 20 | 20 | 4-18 | 250 | 375 | 440 | 38 | |

| 100 | 280 | 195 | 60 | 135 | 3 | 22 | 8-18 | 250 | 500 | 515 | 50 | |

| 25 | 5 | 300 | 215 | 80 | 55 | 3 | 24 | 8-18 | 280 | 615 | 600 | 68 |

| 200 | 8 | 325 | 245 | 210 | 85 | 3 | 26 | 8-18 | 280 | 820 | 740 | 25 |

| 250 | 10 | 350 | 280 | 240 | 210 | 28 | 8-23 | 400 | 980 | 830 | 170 | |

| 300 | 12 | 400 | 335 | 295 | 265 | 3 | 30 | 12-23 | 400 | 1150 | 1020 | 210 |

| 350 | 14 | 450 | 405 | 355 | 320 | 3 | 32 | 12-25 | 450 | 12 | 1230 | 260 |

| 400 | 16 | 500 | 52 | 410 | 375 | 34 | 12-25 | 500 | 1455 | 1450 | 480 | |

| 450 | 18 | 550 | 470 | 435 | 38 | 16-25 | 600 | 1545 | 1635 | 620 | ||

| 500 | 20 | 600 | 580 | 525 | 485 | 4 | 40 | 16-30 | 600 | 1735 | 1855 | 805 |

| 15 | 1/2 | 650 | 640 | 585 | 545 | 4 | 44 | 20–30 | 650 | 110 | 1990 | 880 |

| 20 | 3/4 | 700 | 705 | 650 | 608 | 4 | 46 | 20-34 | 650 | 20 | 2235 | 920 |

Related Products

Customize Your Valve!

Tell Us Your Requirements

Provide valve details such as size, pressure, material, etc.

You can also upload datasheets or drawings directly.

You can also upload datasheets or drawings directly.

Receive a Quote and Solution ≤ 2 Hours

Fill out this form to get a quote and solution in less than 2 hours, making your projects easier to manage and purchases smoother.

Get Drawings and Datasheets ≤ 6 Hours

For standard valves, we deliver drawings or datasheets within 6 hours. For custom valves or large projects, we can provide them within 24 hours.

Get a quote