Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook: https://www.facebook.com/profile.php?id=61563865935136

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

Valves are an essential component in any piping or fluid system, serving to regulate the flow of liquids, gases, or other substances. Among the wide variety of valve materials, copper valves are particularly valued for their durability, corrosion resistance, and ability to handle high temperatures. Copper valves come in various types, each suited for specific applications in plumbing, HVAC, industrial processes, and more. This blog will explore the key aspects of copper valve types, including their features, advantages, common applications, and how to select the right valve for your needs. By understanding the different types of copper valves and their applications, you can make informed decisions and ensure the long-term efficiency of your system.

What Are Copper Valves?

Copper valves are valves made from copper or copper alloys such as brass or bronze. These valves are known for their excellent thermal and electrical conductivity, corrosion resistance, and antimicrobial properties, making them ideal for applications in plumbing, water distribution, and heating systems. Copper valves are often used in both residential and industrial settings due to their reliability and longevity. The most common types of copper valves include gate valves, ball valves, check valves, globe valves, and pressure-reducing valves. Each type has unique characteristics and is designed for specific tasks, such as controlling flow, preventing backflow, or regulating pressure.

Types of Copper Valves and Their Applications

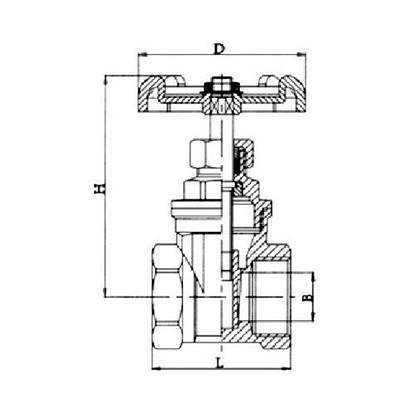

Gate Valves

Gate valves are designed to start or stop the flow of fluid in a pipeline. They feature a sliding gate mechanism that moves up and down to open or close the valve. Gate valves are commonly used in systems where full, unobstructed flow is needed, such as in water supply lines.

- Advantages: Minimal flow resistance, suitable for on/off applications.

- Applications: Plumbing systems, water distribution, and irrigation.

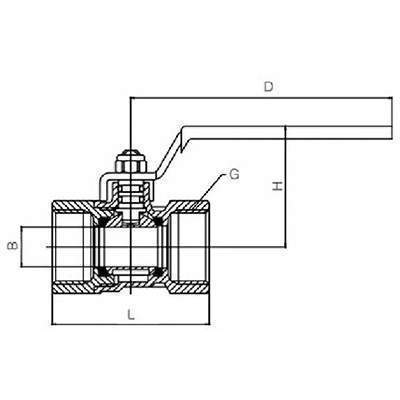

Ball Valves

Ball valves are versatile valves that use a spherical disc to control fluid flow. The ball has a hole in the middle, and when aligned with the pipe, it allows flow; when rotated 90 degrees, it stops the flow. These valves are known for their durability and ease of operation.

- Advantages: Quick to operate, leak-proof, and long-lasting.

- Applications: HVAC systems, chemical processing, and residential plumbing.

Check Valves

Check valves, also known as one-way valves, are designed to prevent backflow in a system. They allow fluid to flow in only one direction and automatically close when the flow reverses. Copper check valves are widely used in water supply systems and pumps.

- Advantages: Prevents contamination and backflow, low maintenance.

- Applications: Water pumps, plumbing systems, and HVAC systems.

Globe Valves

Globe valves are used for regulating fluid flow in a pipeline. They feature a movable disk that can be adjusted to increase or decrease the flow. These valves are ideal for applications that require precise flow control.

- Advantages: Good throttling capability, easy to maintain.

- Applications: Steam systems, cooling systems, and fluid control systems.

Pressure-Reducing Valves

Pressure-reducing valves are designed to lower and regulate the pressure of fluid in a system. These valves ensure that downstream equipment and pipelines are not damaged by excessive pressure.

- Advantages: Protects system components, maintains consistent pressure.

- Applications: Water distribution systems, residential plumbing, and industrial processes.

Key Features of Copper Valves

Copper valves offer several advantages over valves made from other materials. These features make them a preferred choice in various industries.

Corrosion Resistance

Copper and its alloys are naturally resistant to corrosion, which ensures a longer lifespan and reduced maintenance needs.

Thermal Conductivity

Copper valves can handle high-temperature fluids effectively, making them suitable for heating systems and steam applications.

Antimicrobial Properties

Copper has natural antimicrobial properties, which makes copper valves ideal for use in potable water systems, preventing the growth of harmful bacteria.

Durability

Copper valves are highly durable and can withstand high pressures and temperatures without deforming or cracking.

Easy Installation

Copper valves are lightweight and easy to install, which reduces labor costs and installation time.

Table: Comparison of Copper Valve Types

| Type of Valve | Key Features | Common Applications |

|---|---|---|

| Gate Valve | On/off flow control, minimal flow resistance | Water supply, irrigation, and plumbing |

| Ball Valve | Quick operation, leak-proof, durable | HVAC systems, residential plumbing |

| Check Valve | Prevents backflow, low maintenance | Pumps, plumbing systems |

| Globe Valve | Precise flow control, easy to maintain | Steam systems, fluid control |

| Pressure-Reducing Valve | Regulates and lowers pressure, protects system | Water distribution, industrial processes |

How to Select the Right Copper Valve

Choosing the right copper valve for your application involves several considerations. Here are some key factors to keep in mind:

Application Requirements

Understand the specific requirements of your system, such as flow rate, pressure, and temperature. Different copper valve types are designed for different tasks, so ensure the valve you select meets your needs.

Valve Size

Select a valve size that matches the size of your pipeline. An incorrectly sized valve can cause pressure drops or flow restrictions.

Material Compatibility

Ensure the valve material is compatible with the fluid being transported. Copper valves are ideal for water, steam, and certain chemicals, but may not be suitable for highly corrosive fluids.

Operating Conditions

Consider the operating conditions of your system, including pressure and temperature. Copper valves can handle high-pressure and high-temperature applications, but it’s important to confirm their suitability for your specific system.

Maintenance Requirements

Choose a valve that is easy to maintain and repair. Copper valves are known for their durability and low maintenance, making them a cost-effective choice.

Conclusion

Copper valves are a versatile and reliable choice for a wide range of applications, from plumbing and water distribution to industrial processes and HVAC systems. With their excellent corrosion resistance, durability, and thermal conductivity, copper valves provide long-lasting performance and require minimal maintenance. By understanding the different copper valve types and their applications, you can choose the right valve for your specific needs and enhance the efficiency of your system.

FAQ

What are the main types of copper valves?

The main types of copper valves include gate valves, ball valves, check valves, globe valves, and pressure-reducing valves. Each type serves a specific purpose in controlling fluid flow, pressure, or direction.

Where are copper valves commonly used?

Copper valves are commonly used in plumbing systems, HVAC systems, water distribution networks, and industrial processes. They are also popular in residential applications due to their durability and corrosion resistance.

What are the advantages of using copper valve types in plumbing systems?

Copper valve types are highly advantageous in plumbing systems due to their corrosion resistance, durability, and ability to handle high temperatures. Their natural antimicrobial properties also make them ideal for potable water systems, ensuring safe and hygienic water flow.

How do copper valve types compare to valves made from other materials?

Copper valve types offer unique benefits such as excellent thermal conductivity, resistance to corrosion, and long-lasting performance. While materials like stainless steel or PVC may have specific applications, copper valves are a versatile choice for plumbing, HVAC, and industrial systems.

Can copper valve types be used in chemical processing systems?

Yes, copper valve types can be used in chemical processing systems, but it’s important to ensure compatibility with the chemicals involved. Copper is resistant to many substances, but highly acidic or corrosive chemicals may require specialized valve materials.

Are copper valve types suitable for outdoor applications?

Copper valve types are suitable for outdoor applications due to their resistance to weathering and corrosion. However, proper insulation or coating is recommended in extreme environments to prolong their lifespan.

How can I maintain the efficiency of copper valve types over time?

To maintain the efficiency of copper valve types, regularly inspect them for any signs of wear, corrosion, or debris buildup. Ensure proper lubrication of moving parts and replace worn components as needed to keep the valve functioning optimally.